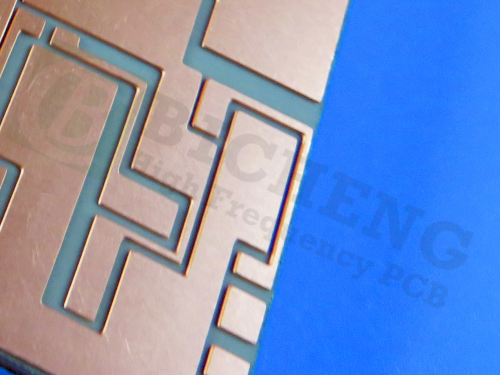

10oz Heavy Copper TU-865 PCB – Double-Sided 3.0mm Thick for Harsh Environments

1. Basic PCB Specifications

| Specification | Details |

|---|---|

| Board type | 2 layers |

| Material type | TU-865 |

| Solder mask | Both sides, Green |

| Silkscreen print | Top side, white |

| Surface finish | ENIG |

| Total board thickness | 3.0mm +/- 10% |

| Board size | 120mm x 210mm = 1 PCS |

| Minimum hole size | 0.4mm |

| Solder mask thickness | 100um |

| Minimum trace line width | 600um |

| Minimum spacing | 600um |

2. PCB Stack-up: 2-layer Rigid PCB (Component side at top)

| MATERIAL | COPPER LAYER | THICKNESS (um) | SPECIFICATION |

|---|---|---|---|

| COPPER | 1 | 350 | |

| TU-865 | Core | 3000 | IPC-4101/24 |

| COPPER | 2 | 350 |

3. PCB Statistics:

- Components: 38

- Total Pads: 98

- Thru Hole Pads: 35

- Top SMT Pads: 26

- Bottom SMT Pads: 12

- Vias: 52

- Nets: 2

4. Type of artwork supplied:

- Gerber RS-274-X

5. Quality standard:

- IPC-Class-2

6. Availability:

- Worldwide

7. Introduction of TU-865

The TU-865 Tg200 material is composed of epoxy resin and E-glass fabric. It is a halogen-free material designed for harsh environments, high-reliability applications, and superior electrical performance. TU-865 meets the UL94V-0 flammability classification by incorporating phosphorus and nitrogen compounds. This material is compatible with the AOI process and exhibits UV-blocking characteristics. TU-865P is a prepreg designed for use with TU-865 laminate to create multilayer printed wire boards. TU-865 is also available for single and double-sided applications. This series of green materials eliminates halogenated resins, thereby addressing environmental concerns while maintaining excellent performance. These products are suitable for boards that must endure severe thermal cycling or excessive assembly work. TU-865 laminates also demonstrate superior chemical resistance, dimensional stability, and moisture resistivity for lead-free soldering assembly and CAF resistance.

8. Key features (TU-865)

- High Tg (DSC) of 200°C, Tg (TMA) 185°C

- Dielectric constant of 4.4 @ 10GHz

- Dissipation factor of 0.014 @ 10GHz

- Low coefficient of thermal expansion

- Excellent moisture resistance of 0.13%

- Lead-free processing compatible

- Anti-CAF capability

- Exceptional through-hole and soldering reliability

- Environmentally friendly materials

9. Typical applications

- Automotive

- Harsh environments

- Servers

- Telecom

- Base stations